The most dangerous corrosion is the kind you can’t see.

It’s easy to inspect for rust on a gun barrel, or pitted metal on a vehicle. That’s what’s known as “gross corrosion.” What’s much harder to spot is “microscopic-level corrosion” on small but critically important components such as circuits, wiring, and telecommunications equipment.

As the modern military depends more and more on technology, the risk of microscopic-level corrosion increases. Something like a circuit-board doesn’t have much material to begin with, so small amounts of corrosion create disproportionately large problems. Even minimal corrosion can affect calibration and performance.

Military aircraft are at particular risk, not only because of their increasing use of technology, but also because the consequences of equipment failure can be catastrophic. The most recent data found that 30% - 40% of avionics failures were due to corrosion.*

Fortunately there are steps you can take to mitigate and prevent both gross and microscopic corrosion. If you have to store assets outside, protective covers are a good first line of defense. You just need to make sure the cover material is both waterproof and air-permeable. (Otherwise heat and moisture build up under the cover and create a “greenhouse effect” which can actually accelerate corrosion.)

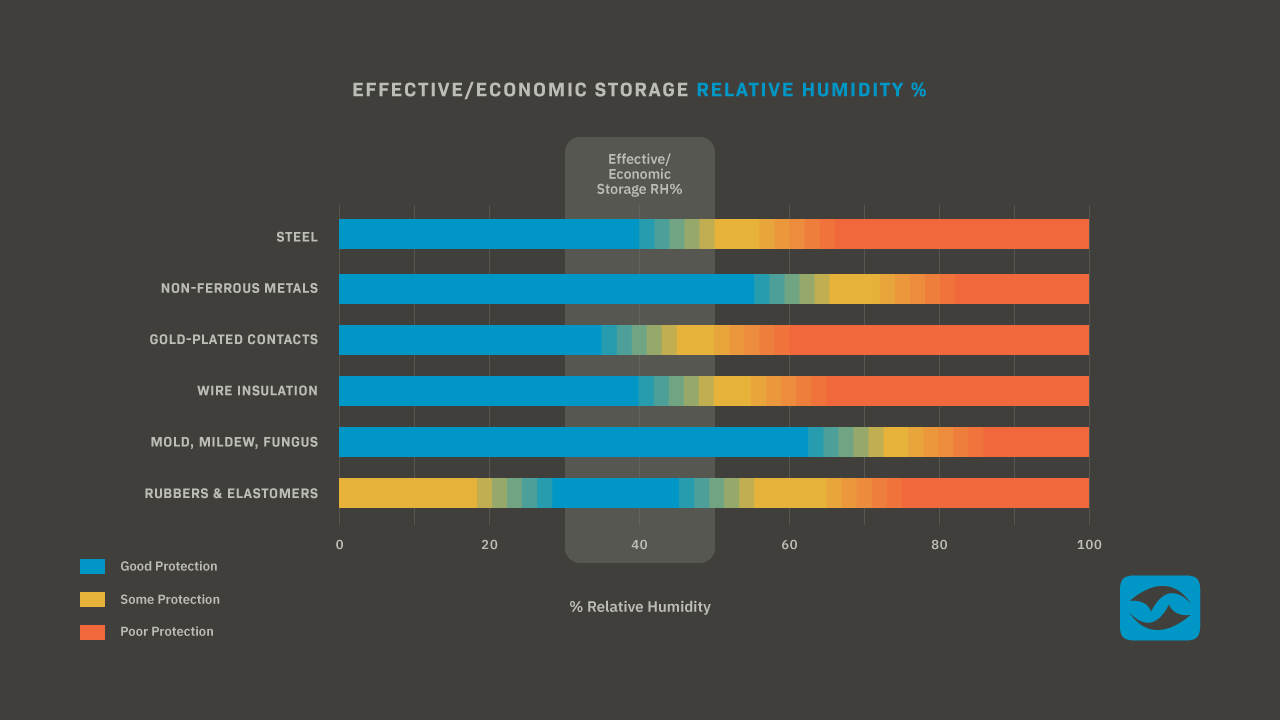

Of course the ideal solution is to store assets and parts in humidity-controlled facilities. Electronics begin corroding around 40% RH, so by maintaining RH levels at 35% (plus/minus 5%), you can prevent corrosion altogether.

As you can see, corrosion isn’t just a readiness issues, or a cost issue, it can also be a safety issue. Contact us to learn more about ways you can reduce the risks of corrosion.

*Tri-Service Technical Manual NAVAIR 01-1A-509-1, TM 1-1500-344-23-1, TO 1-1-689-1. CLEANING AND CORROSION CONTROL VOLUME I. CORROSION PROGRAM AND CORROSION THEORY. 01 March 2005.