Protective Covers

Even the most rugged equipment deteriorates when exposed to the elements, putting readiness at risk and increasing maintenance costs. Protective covers are a proven and cost-effective line of defense against mold, mildew, and corrosion.

Utilizing highly technical textiles, Cocoon covers meet all the requirements of the AMRDEC Protective Cover Performance Specification, including air-permeability which prevents the “greenhouse effect” (which can actually accelerate corrosion). See below for a full list of features.

Cocoon Covers

can be used for:

Vehicles

Aircraft

Artillery

Ground Support Equipment

Watercraft

Technology in a textile.

Cocoon’s patented covers represent a major breakthrough in cover performance, making them essential equipment for your essential equipment. Key features include:

Highly Air-Permeable (not just “breathable”)

Hydrophobic (wet weight = dry weight)

Oleophobic (repels fluids, oils, fuels)

No use of VCI chemicals (which may actually cause corrosion and can be harmful to soldier health)

Download the brief for a more detailed explanation of our Protective Covers, including a listing of all the features that satisfy the AMRDEC Protective Cover Performance Specification.

For other points of interest check out the Protective Covers Blog Pack.

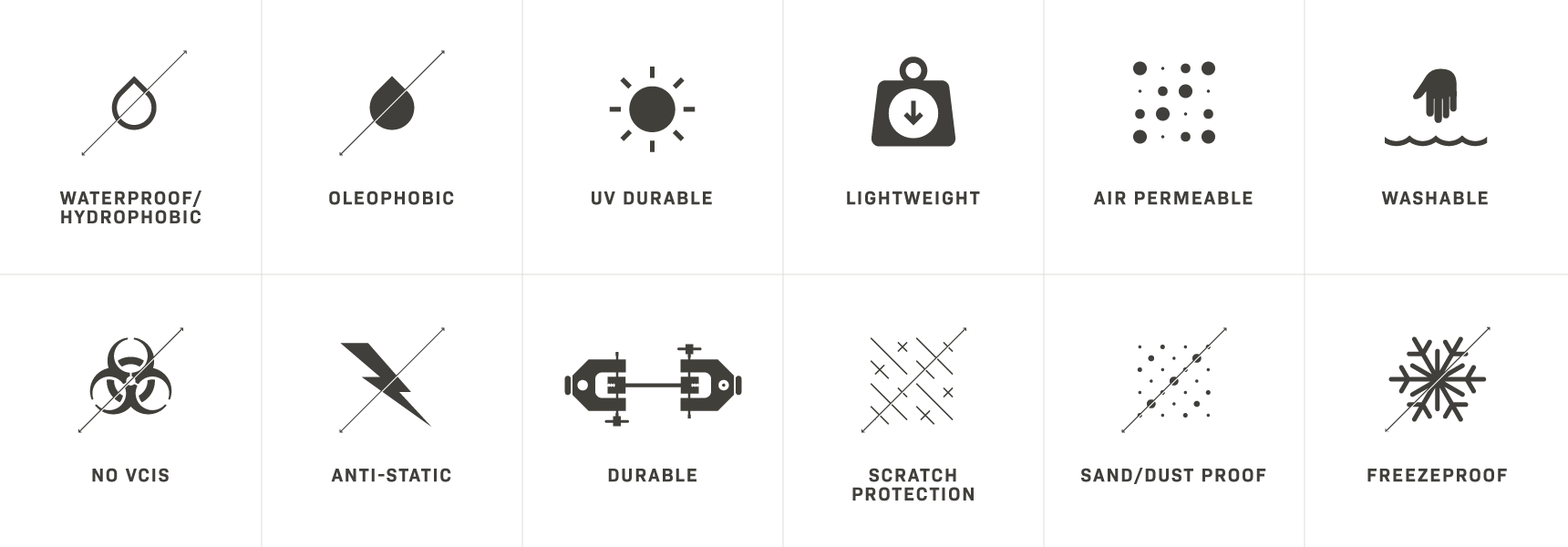

Cocoon Protective Cover Features

While each feature is important on its own, the combination of all features is required to ensure a protective cover will be truly effective.

“The use of equipment covers has been found to enhance corrosion-resistance of equipment by reducing exposure to things such as temperature, relative humidity, sulfur dioxide deposition, chloride ion deposition, and ultraviolet rays.”

Memorandum from the Dept. of the Army - Acquisition Logistics & Technology 2017

Example Applications

Corrosion affects every kind of critical asset, which is why we cover everything from rotary wing aircraft and GSE to vehicles and weapon systems.

CHINOOK COVER KIT

APACHE COVERS

BLACKHAWK TAIL ROTOR COVER

AH-1 NOSE COVER

ARMORED KNIGHT COVER

GET 35 TRAILER COVER

BRADLEY COVER

A/A49E-27 20mm Automatic Gun

MEP SERIES GENERATORs

MTVR COVERS

M777 COVER

PSU BOAT COVER